مهارتهای مورد نیاز یک مهندس بهرهبردار برای استخدام در شرکتهای نفتی ایرانی و خارجی

پس از بررسی دهها آگهی استخدامی بهترین شرکتهای نفتی جهان، لیستی از مهارتهای مورد نیاز یک مهندس بهرهبردار برای استخدام در این شرکتها را تهیه کردهام و در ادامه با شما به اشتراک میگذارم.

* این لیست مدام در حال بروزرسانی میباشد.

“Required technical skills”

- Utilize engineering best practices to develop and implement optimal surface and downhole designs.

- Review, explain, and recommend solutions to drive improvements in daily production performance.

- Develop and implement an optimized artificial lift lifecycle for all wells.

- Determine new well choke management strategy.

- Manage and optimize chemical treatment and flow assurance programs.

- Monitor and analyze KPI data to identify performance improvement opportunities.

- Optimize work flows so that the actions performed in in the field will built the most overall value to the business.

- Knowledge in gas lift, rod lift, and plunger lift design, troubleshooting and optimization.

- Experience with nodal analysis to implement optimal drawdown and FBHP management.

- Experience with surface facility design, damage mechanisms, operational troubleshooting, and best practices.

- Experience with cost modeling, root cause analysis, system optimization.

- Experience with data analytics, SQL, python, and Power BI.

- Strong presentation skills.

- Strong understanding of process flow and equipment used for separation of fluids on common oil and gas production wells.

- Familiarization with: Smartsheet, AutoCAD, Promax, Bluebeam, Aspen, Synergy, SKM Power Tools, Ariel Performance.

- Proficiency with MS Office.

- Preparing detailed technical installation and troubleshooting procedures.

- Excellent oral and written communication skills.

- Excellent negation skills.

- Excellent time management skills.

- Conduct engineering studies to resolve complex technical problems that may occur.

- Diagnose production enhancement opportunities and make recommendations for improving performance.

- Provide technical and financial analysis support to field operations in efforts to control and reduce LOE (Lease Operating Expense).

- Fracture stimulation design.

- Ensure daily KPIs are met or exceeded.

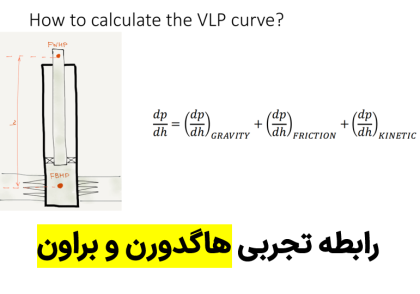

- Utilizing both IHS Harmony and PROSPER, model and analyze a well’s productivity and potential.

- Identify and discrepancies between actual production and potential with the goal of improving productivity and ensuring each well’s potential is met.

- Leveraging the PETEX programs (PROSPER, GAP and MBAL), model and evaluate the integrated “subsurface to surface” network to identify bottlenecks and their possible causes to propose solutions aiming at optimizing the asset’s production and profitability.

- Track and implement the annual data acquisition plan for production and reservoir requirements.

- Continually identify, evaluate (technical/economic) and propose innovative production technology strategies to improve well and asset operational performance.

- Manage the well integrity status for all wells.

- Prepare detailed well intervention programs and supervise jobs in the field.

- Determine the equipment sizing and metallurgy that is suitable for good conditions and operational requirements.

- Artificial lift experience including design, installation, commissioning, operations, optimizations, troubleshooting, and failure analysis of gas lift systems.

- Deliver day-to-day field management activities including well and system monitoring, surveillance, and regulatory testing using real time data and digital tools.

- Familiar with pressure transient analysis using KAPPA Saphir.

- Familiarity in the data analytics space (Advanced VBA, PowerQuery, PowerPivot, Python, Power BI, Spotfire) Establishing Key Performance Indicators (KPIs) for use in creating production dashboards for high level surveillance.

- Working knowledge of nodal analysis software (e.g. Prosper, GAP, IVM, IFM).

- Must be able to handle multiple concurrent tasks with an ability to prioritize and manage tasks effectively.

- Support monitoring, managing, and remediating downhole corrosion, hydrate, scale, wax, paraffin and asphaltenes.

- Responsible for metering and allocation accuracy/consistency between wells.

- PLT Interpretation

- Prepare field reviews, wellbore schematics, cost estimates and procedures for downhole and surface operations; analysis of production and pressure data; basic understanding of reservoir engineering and economic evaluations.

- Prepare project timelines, cost estimates and procedures, review reports and records for accuracy, tracks project costs, verify invoices and may participate in post project analysis.

- Assume project management responsibilities and/or mentor less experienced staff.

- Understand and properly applies HSE guidelines.

- Write procedures and justification for approved optimization / well intervention / remedial projects in assigned areas.

- Prepare concise reports and presentations as required for management.

- Identify underperforming wells/areas and recommend appropriate action so that the asset is optimized.

- Perform trend analyses, prepare forecasts and budgets as needed.

- Designing pipeline network (oil, gas, and water) and building hydraulic models using approved software such as PIPESIM and OLGA.

- Optimize the surface oil, gas and water production facility performance including developing/implementing engineered solutions for issues that may be limiting production, productivity and efficiency.

- Conduct production analysis to drive strategic change in operational activities.

- Identify cost reduction opportunities.

پیشنهاد ویژه: آموزش جامع درس مهندسی بهرهبرداری (با رویکرد صنعتی)

پیشنهاد ویژه: آموزش رزومهنویسی حرفهای (ویژه صنعت نفت و گاز)

با بررسی تمام این موارد یک نتیجهگیری کلی میتوان کرد:

در ایران و دنیا، یادگیری نرمافزارهای پراسپر، گپ و سفیر برای تمام مهندسان بهرهبرداری ضروری است. همچنین، یادگیری نرمافزارهای تحلیل و مصورسازی داده مانند Power BI و ماکرونویسی در اکسل مزیت محسوب میشود.

باور کنید اگر بر روی همین چند نرمافزار به تسلط کامل برسید، یک سر و گردن از بقیه دوستان و همکاران بالاتر خواهید بود! شکی در این جمله نداشته باشید.

دوره جامع چاهآزمایی (طراحی، عملیات، تفسیر با نرمافزار سفیر)

آموزش ویدئویی درس مهندسی بهرهبرداری (با رویکرد صنعتی)

آموزش نرمافزار پراسپر (Prosper)

آموزش مقدماتی نرمافزار گپ (GAP)

آموزش ویدئویی مفاهیم و تئوریهای نمودار نگار تولید + تدریس نرمافزار امراد (Emeraude)

آموزش ویدئویی نرمافزار پایپ سیم (دوره مقدماتی و تکمیلی)

پیشنهاد ویژه: پکیج آموزش مهندسی بهرهبرداری با ۱۵ درصد تخفیف

پیشنهاد ویژه: مهارتهای مورد نیاز یک مهندس مخزن برای استخدام در شرکتهای نفتی ایرانی و خارجی

دیدگاهتان را بنویسید